The issue of marine plastic waste has become a global concern, posing a significant threat to marine life and the environment. Abandoned fishing nets and gear account for nearly half of this total. Fishing nets discarded in the ocean damage the marine ecosystem and become an underwater killer of marine life. Institutions, governments, and non-profit organizations worldwide are seeking solutions to reduce the amount of fishing nets entering the ocean. Diving and salvage operations have also taught fishermen the importance of recycling nets to save the marine environment.

Recycling discarded fishing nets is one of the best ways to solve the problem of marine plastic waste. However, due to the special nature of fishing nets, recycling still has some difficulties.

1. There are many different types of fishing nets, and the weight of each recycled net varies greatly, ranging from a few kilograms to several tons, making miniaturization difficult.

2. Recycled nets contain a large amount of sand and fish bones, making cleaning and impurity separation challenging.

3. There are no single-material fishing nets on the market. A net may contain a variety of materials, primarily floating PEPP and sinking PAPET, which have similar densities. This separation of floating and semi-sinking materials is poor or impossible.

4. Fishing nets are mostly monofilament, and the size of the shredded monofilament nets is small. Improper separation methods can result in significant losses.

5. The water content of the cleaned nets is high.

6. The size of the shredded nets is small, making them prone to clogging during the pelletizing process.

7. After cleaning, the pelletizing filtration accuracy is low, failing to meet the quality requirements of high-end ECO filament downstream applications.

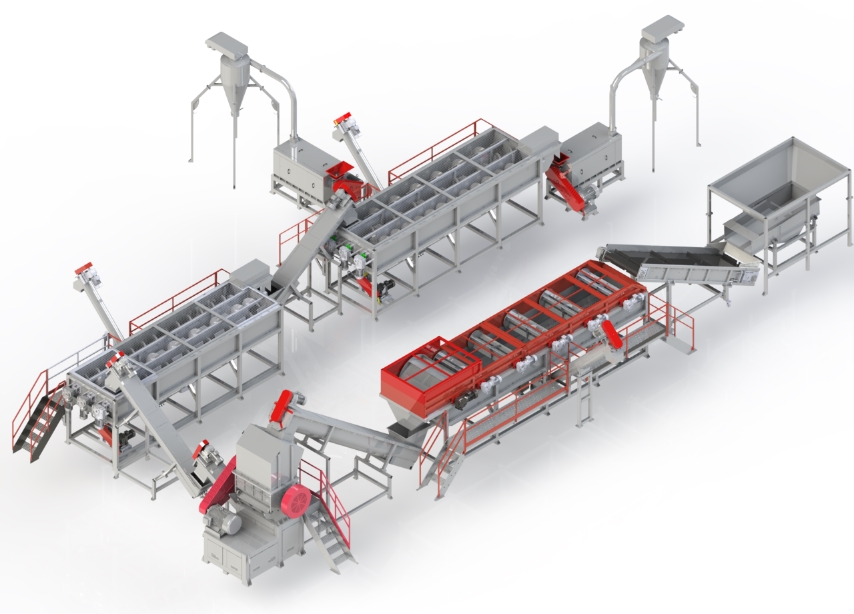

The XinBei machinery fishing net recycling process can effectively solve several recycling difficulties. Various recycling processes are developed for different fishing nets, mainly based on PP, PE and, PA, PET.

1. A wide chain conveyor is used for loading and equip with a single-shaft shredder , effectively solving the problem of pre-shredding fishing nets with large weight and size variations.

2. The pre-shredded fishing nets are conveyed to a rinsing machine, where a specially designed structure effectively breaks up the nets and separates sediment, fish bones, and other sinking materials from the PP and PE.

3. The rinsing discharge section is equipped with a lift-type filter, which provides cleaning and preliminary drying functions for PP and PE.

4. The fishing net monofilaments are shredded again.

5. Three high-speed hot washers are added for deep cleaning of PA and PET fishing nets, addressing the problem of clogging in the pelletizing section. A closed-loop hot wash water circulation system is also installed to save energy.

6. The fishing nets continuously pass through different types of rinsing tanks, ensuring thorough rinsing and removal of impurities. The latter is equipped with a dehydrator for dehydration and pressing.

7. A pipeline drying system thoroughly heats and dries the cleaned fishing net monofilaments, separating air and reducing the moisture content to below 8%, meeting pelletizing requirements.

8. The granulation process uses a compaction cutting chamber. After pre-agglomeration, it enters a double-station vacuum screw equipped with a 50-60 mesh self-cleaning filter and then enters a secondary screw equipped with a 320/400 mesh filter to produce high-quality granules suitable for wire materials.

The social and economic value of fishing net recycling and future development.

Fishing nets left in oceans and rivers threaten aquatic life and damage the ecological environment.

Rather than simply reusing discarded fishing nets, recycling, cleaning, and pelletizing them allows them to be recycled into more consumer products. Furthermore, more recycled fishing gear can be reused, effectively boosting the fishery economy.